Key Advantages of Pneumatic Sanitary Butterfly Valves for Automated Beverage Filling Lines

by admin

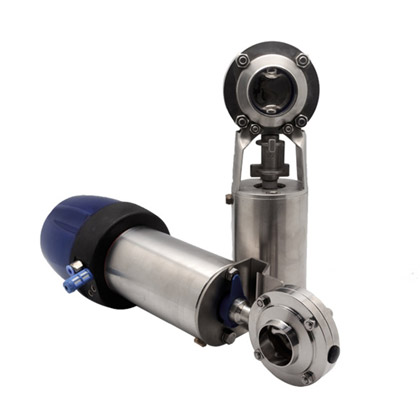

by adminAutomated beverage filling lines rely on three core needs: speed, hygiene, and precision. Pneumatic-driven fluid control tools, especially those made for food-grade use, meet these needs well. The pneumatic Sanitary Butterfly Valve is a trusted option here—it solves common issues in making drinks from sodas to fresh juices while fitting modern filling line operations. Below are its main benefits, simplified for clear understanding.

Fast Response for High-Speed Filling

Core advantage: Pneumatic actuation works quickly with 0.5–5 seconds per on/off cycle.

Value for filling lines: Matches the pace of lines that fill hundreds of bottles or cans per minute.

No delays when switching between different fluids like syrup, water, finished drinks.

Prevents bottlenecks and reduces overfilling or underfilling caused by slow valves.

Hygiene Design That Meets Beverage Rules

Core advantage: Built for safety with materials and structure focused on cleanliness.

Value for filling lines: Avoids contamination and follows industry standards.

Body and disc use 316L stainless steel, which resists corrosion from acidic or sugary drinks like orange juice or soda.

Seals are made of EPDM or food-grade silicone. These materials are FDA-approved, so they won’t add bad smells or leak chemicals into drinks.

Easy cleaning is enabled by a smooth, gap-free interior and easy-to-disassemble structure. This design works with CIP in-place cleaning systems and cuts downtime for daily sterilization.

Stable Control for Consistent Filling

Core advantage: Pneumatic power lets you adjust the valve’s disc angle, going beyond simple on/off functions.

Value for filling lines: Handles different drink types and keeps fills accurate.

Controls flow for thick juices to maintain steady speed, and manages pressure for sodas to avoid losing fizz.

Maintains consistent performance even when line pressure changes. This scenario is common when multiple valves run at the same time.

Reduces waste caused by uneven fills.

Low Maintenance for Non-Stop Production

Core advantage: Features a simple, strong structure with fewer moving parts.

Value for filling lines: Minimizes downtime, which is critical for maximizing output.

Experiences less wear and tear compared to complex electric valves.

Routine care like replacing seals or cleaning can be done quickly. There’s no need to fully remove the valve from the line.

Lowers maintenance costs and extends the valve’s life in high-cycle use.

Easy Integration with Automated Control Systems

Core advantage: Compatible with common automated control setups used in beverage plants.

Value for filling lines: Boosts overall line automation and reduces manual intervention.

Works with PLC systems to receive and execute control signals. This allows for remote operation, so workers don’t need to be near the filling area.

Sends real-time status feedback, such as whether the valve is open or closed. This helps monitor line operations and quickly identify issues.

Fits into existing automated workflows without requiring major modifications to the filling line’s control panel.

Conclusion

For automated beverage filling lines, the pneumatic Sanitary Butterfly Valve solves key problems: it’s fast enough for high throughput, clean enough for safety rules, precise enough for consistent fills, durable enough for non-stop work, adaptable to different pressures, and easy to integrate with automation. These benefits mean better line efficiency, less waste, and reliable drink quality—all important for competing in fast-moving markets.

To see how our pneumatic Sanitary Butterfly Valve fits your specific filling line needs, check our product page for detailed specs and real application examples.