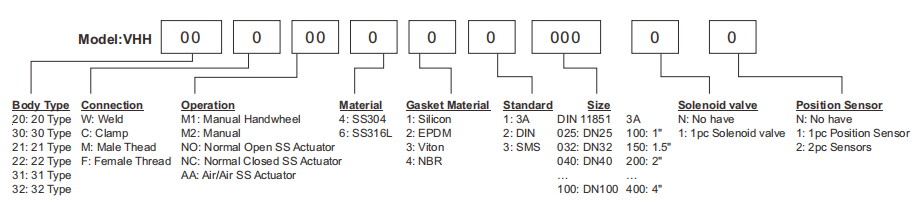

FEATURES Clamped housing connection Wetted Steel Material: SS304/SS316L Size :1"-4" or DN25-DN100 EPD...

InquireVHH series shut-off and divert seat valve provides solutions for the most stringent hygienic and aseptic processes requirements in the beverage, food, dairy and pharmaceutical industries.The valve series provides the best basis for efficient and safeproduction processes due to the wide variety of options provided byour modular system, ease of maintenance, ceanability, and theoptions for the valves to meet the latest hygiene and asepticrequirements.

Working Temperature Range: -10°C to +120°C (EPDM per FDA)

Max. Working Pressure: 1000 kPa (10 bar)

Min. Working Pressure: Full vacuum

Air Pressure for Actuator: 500 to 700 kPa (5 to 7 bar)

Air Connections Compressed air: Female R 1/8" (BSP)

Wetting Steel Parts: SS304/SS316L

Other Steel Parts: SS304

Seat Seal: EPDM per FDA 177.2600

Connection: Clamp End/Weld End/Male End

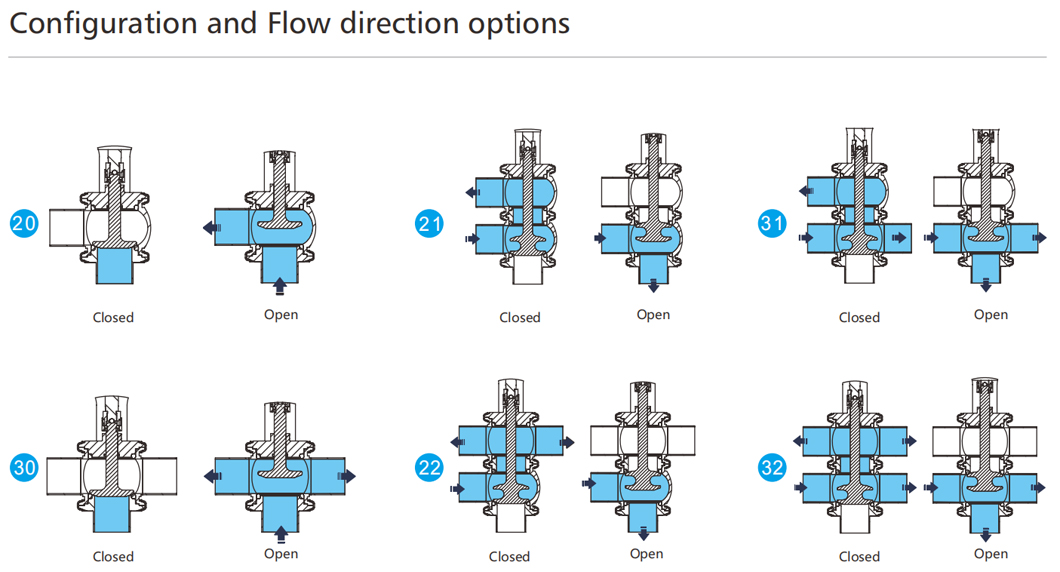

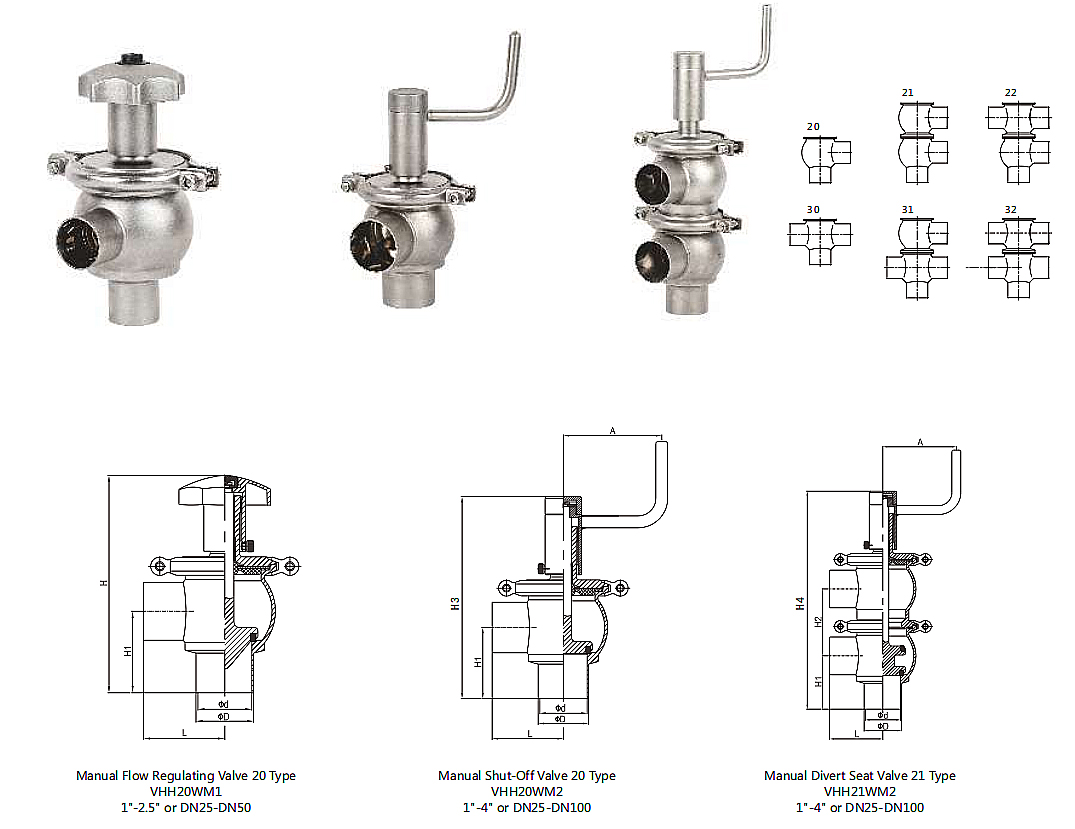

Body type: 20, 21, 30, 31, 22, 32

WORKING PRINCIPLE

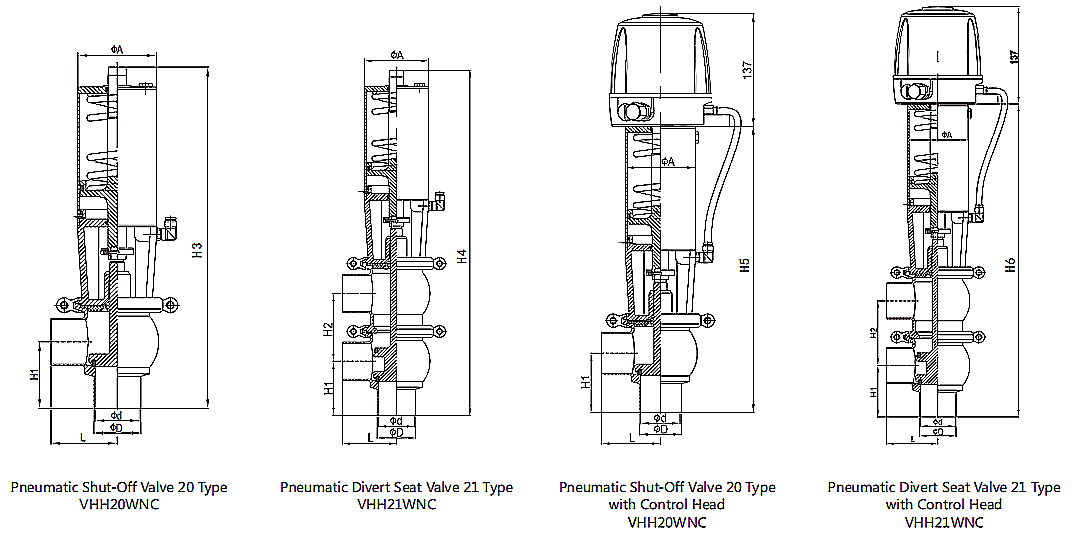

The valve is a pneumatic seat valve in a hygienic and modular designfor a wide field of duties, e.g. as a shut-off valve with two (2) orthree (3) ports or as a change-over valve with three (3) to five (5)ports. The valve is remote-controlled by means of compressed air. lthas few and simple moveable parts which results in a very reliablevalve and low maintenance cost.

MATERIAL

Wetting Steel Parts: SS304/SS316L

Other Steel Parts: SS304

Seat Seal: EPDM per FDA 177.2600

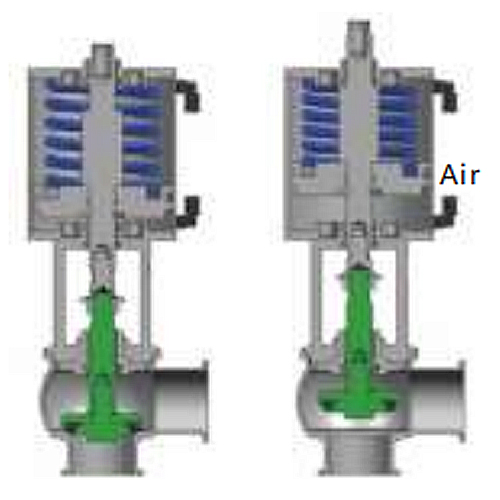

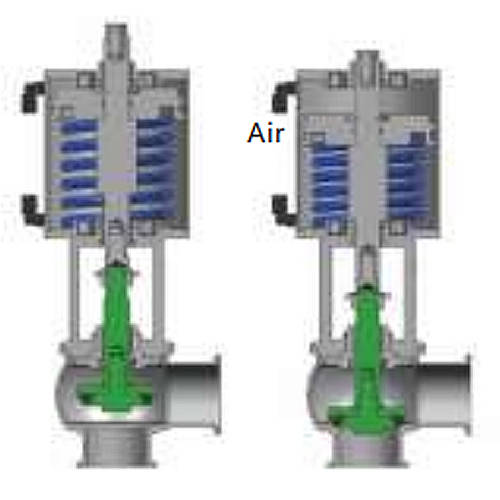

ACTUATOR FUNCTION

Normally Open(NO): Air to Close and Spring to Open

Normally Close(NC): Air to Open and Spring to Close

Double Actuating(A/A): Air to Open and close

FDA Gasket

Clamped housing connection: Seat ring clamped by clamping connection

SURFACE FINISHING

Inside Surface: Bright polished to Ra<0.8umOutside Surface: Matt or Sandblast

OPTION

1. Connection way: Weld, Tri clamp, Male parts2.1 or 2pcs Proximity switches

3. With jacket body

4. Product wetted seals in Silicon, NBR Or FPM5. External Surface finish: Mirror

6. With Control Head

Note: Converting the operating mode from air to open to springto open (and vice-versa) is possible without additional parts!

| Normal Close(NC actuator) | Normal Close(NO actuator) |

|

|

|

Valve is close, when air is suppliedplug lift to open. The built inspring returnsthe valve plug to its close positiononce the air supply is stopped |

Valve is open, when air is supplied,shaft goes down to close. The builtin spring returns the valve plug toit s open position once the airsupply is stopped |

Configuration and Flow direction options

|

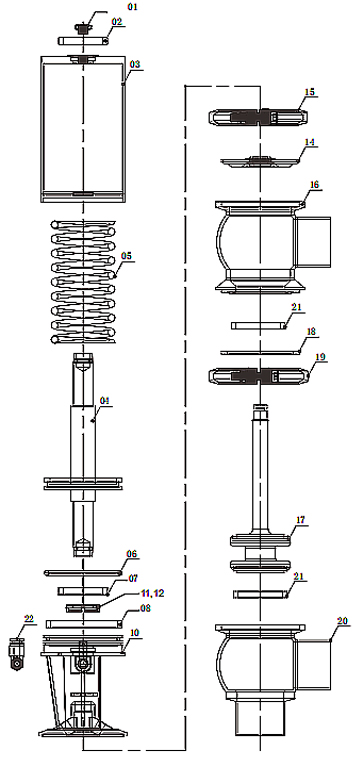

Item | Description | Material | Qty |

| 1 | Silencer | QAI10-4-4 | 1 | |

| 2 | O-Ring | NBR | 1 | |

| 3 | Cyinder | SS304 | 1 | |

| 4 | Piston | SS304 | 1 | |

| 5 | Spring | 60Si2MnA | 1 | |

| 6 | O-Ring | NBR | 1 | |

| 7 | O-Ring | NBR | 1 | |

| 8 | O-Ring | NBR | 1 | |

| 9 | Snap ring | SS304 | 1 | |

| 10 | Bracket | SS304 | 1 | |

| 11 | Gland | PVDF | 1 | |

| 12 | Plate | SS304 | 1 | |

| 13 | Sleeve | Plastic | 1 | |

| 14 | Seal | 304+EPDM | 1 | |

| 15 | Clamp | SS304 | 1 | |

| 16 | Upper Valve Bady | SS304/SS316L | 1 | |

| 17 | Valve Plug | SS304/SS316 | 1 | |

| 18 | Valve Body Seal | EPDM | 1 | |

| 19 | Calmp | SS304 | 1 | |

| 20 | Lower Valve Body | SS304/SS316L | 1 | |

| 21 | Seat Seal | EPDM | 2 | |

|

Material: Other Steel Parts: ss304 Seat Seal: EPDM, FKM per FDA 177.2600 Connection:Clamp End/eld End/Male End Body type: 20,21,30,31,22,32 |

||||

|

Material: Other Steel Parts: SS304 Seat Seal: EPDM, FKM per FDA 177.2600 Connection:Clamp End/eld End/Male End Body type: 20,21,30,31,22,32 |

||||

|

Surface: utside Surface: Matt or Sandblast |

||||

| Size | d | D | H | H1 | H2 | H3 | H4 | A | L |

| 1" | 22.4 | 25.4 | 192 | 72 | 90 | 204 | 295 | 100 | 72 |

| 11/4" | 28.8 | 31.8 | 192 | 72 | 90 | 204 | 295 | 100 | 72 |

| 11/2" | 35.1 | 38.1 | 192 | 72 | 90 | 204 | 295 | 100 | 72 |

| 2" | 47.8 | 50.8 | 192 | 72 | 90 | 204 | 295 | 100 | 72 |

| 21/2" | 59.5 | 63.5 | 201 | 75 | 99 | 213 | 312 | 100 | 80 |

| 3" | 72.2 | 76.2 | / | 98 | 107 | 258 | 364 | 125 | 98 |

| 31/2" | 84.9 | 88.9 | / | 107 | 120 | 272 | 392 | 125 | 107 |

| 4" | 97.6 | 101.6 | / | 127 | 135 | 300 | 434 | 125 | 135 |

| DN25 | 25 | 28 | 192 | 72 | 90 | 204 | 295 | 100 | 72 |

| DN32 | 31 | 34 | 192 | 72 | 90 | 204 | 295 | 100 | 72 |

| DN40 | 37 | 40 | 192 | 72 | 90 | 204 | 295 | 100 | 72 |

| DN50 | 49 | 52 | 192 | 72 | 90 | 204 | 295 | 100 | 72 |

| DN65 | 66 | 70 | / | 98 | 107 | 258 | 364 | 125 | 98 |

| DN80 | 81 | 85 | / | 107 | 120 | 272 | 392 | 125 | 107 |

| DN100 | 100 | 104 | / | 127 | 135 | 300 | 434 | 125 | 135 |

| Size | d | D | H1 | H2 | H3 | H4 | H5 | H6 | A | L |

| 1" | 22.4 | 25.4 | 72 | 90 | 367 | 453 | 353 | 439 | 86 | 72 |

| 11/4" | 28.8 | 31.8 | 72 | 90 | 367 | 453 | 353 | 439 | 86 | 72 |

| 11/2" | 35.1 | 38.1 | 72 | 90 | 367 | 453 | 353 | 439 | 86 | 72 |

| 2" | 47.8 | 50.8 | 72 | 90 | 367 | 453 | 353 | 439 | 86 | 72 |

| 21/2" | 59.5 | 63.5 | 75 | 99 | 373 | 472 | 357 | 456 | 86 | 80 |

| 3" | 72.2 | 76.2 | 98 | 107 | 404 | 509 | 388 | 493 | 108 | 98 |

| 31/2" | 84.9 | 88.9 | 107 | 120 | 443 | 562 | 428 | 548 | 133 | 107 |

| 4" | 97.6 | 101.6 | 127 | 135 | 478 | 612 | 459 | 593 | 152 | 135 |

| DN25 | 25 | 28 | 72 | 90 | 367 | 453 | 353 | 439 | 86 | 72 |

| DN32 | 31 | 34 | 72 | 90 | 367 | 453 | 353 | 439 | 86 | 72 |

| DN40 | 37 | 40 | 72 | 90 | 367 | 453 | 353 | 439 | 86 | 72 |

| DN50 | 49 | 52 | 72 | 90 | 367 | 453 | 353 | 439 | 86 | 72 |

| DN65 | 66 | 70 | 98 | 107 | 404 | 509 | 388 | 493 | 108 | 98 |

| DN80 | 81 | 85 | 107 | 120 | 443 | 562 | 428 | 548 | 133 | 107 |

| DN100 | 100 | 104 | 127 | 135 | 478 | 612 | 459 | 593 | 152 | 135 |

FEATURES Clamped housing connection Wetted Steel Material: SS304/SS316L Size :1"-4" or DN25-DN100 EPD...

InquireFEATURES Wetted Steel Material: SS304/SS316L Size :1"-4" or DN25-DN100 EPDM seat seal per FDA 177.2600...

InquireVR series divert seat valve is a kind of manual hygienic single-seat valve, which is applied to a wide ra...

InquireVR series divert seat valve is a kind of manual hygienic single-seat valve, which is applied to a wide ra...

InquireWenzhou QiMing Stainless Co., Ltd., a leading manufacturer and exporter of precision stainless steel valves and fittings established in 2015, is thrilled to announce the successful completion of its reloca...

Wenzhou, China – [November 7-8] – With the autumn breeze blowing and company flags fluttering, Wenzhou Qiming Stainless Steel Co., Ltd. celebrated a significant milestone in its journey in the stainle

GET A QUOTE